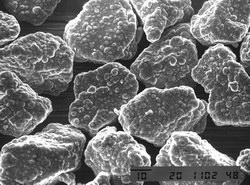

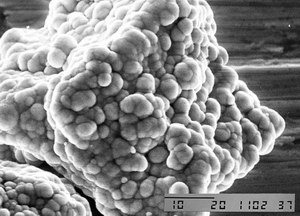

Micron Diamond Powder

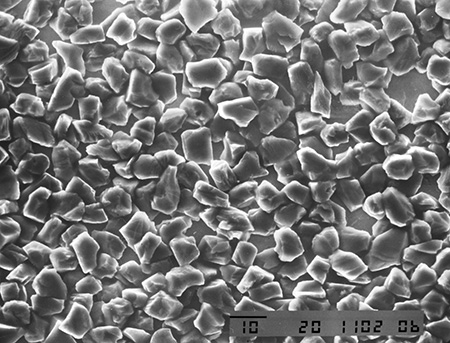

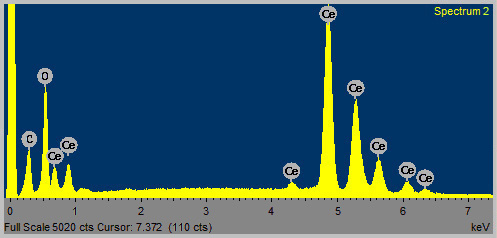

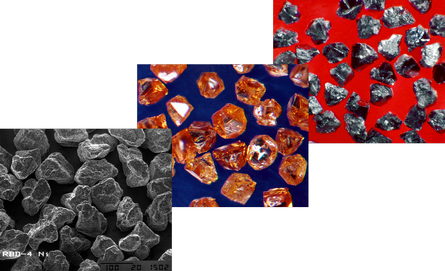

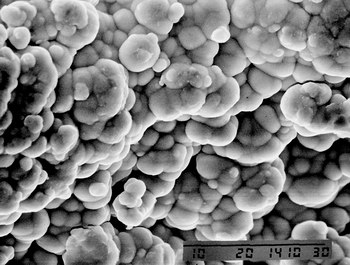

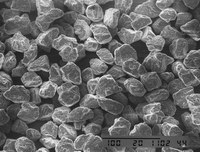

HARIS DIVISION company offers micron powders with the grain size ranging from 60 to 1 micron, obtained by the method of static or centrifugal sedimentation, and sub-micron powders with the size less than 1micron, obtained by the method of classification on super centrifuges from the preliminary processed product of 1micron class.

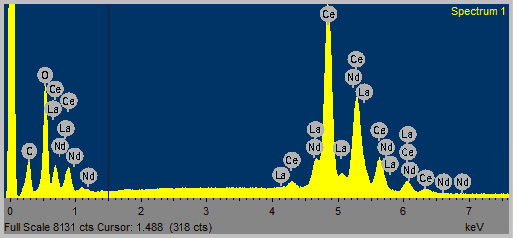

In technology of production an important part play physico-mechanical impact on grains for the purpose of achievement of the necessary granulometric structure and increasing their isometrics. In the HD lab there was worked through new technological schemes of micron powder manufacturing, which allow adjusting granulometric structure, shape factor, field-performance data of powders. This ensures manufacturing of the vast assortment of high quality products.